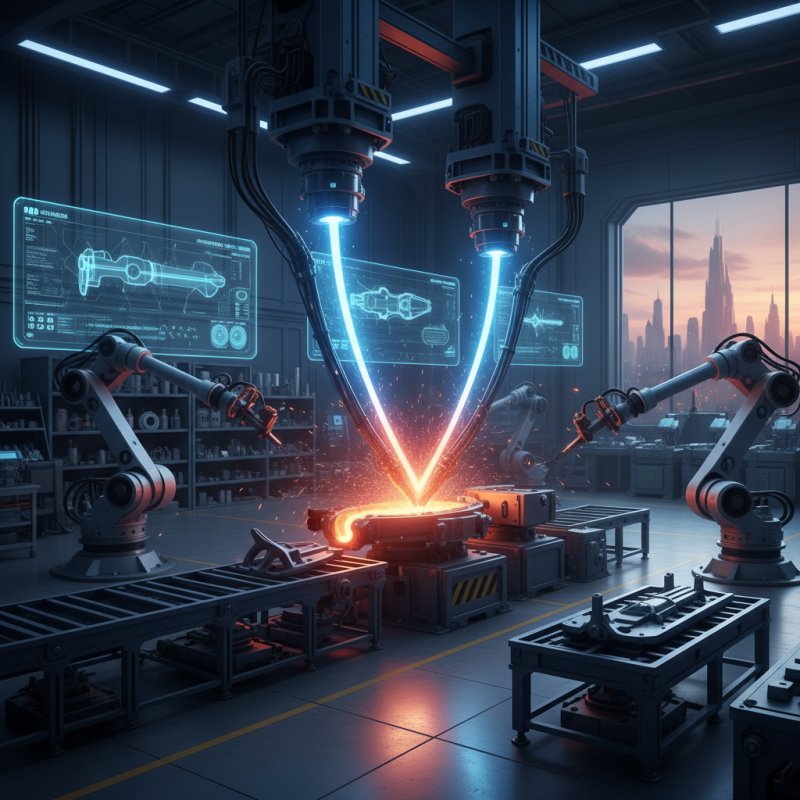

Double Arc Forming techniques play a crucial role in manufacturing processes. This method optimizes shape and enhances product durability. According to recent industry reports, the global market for forming technologies is projected to reach $13 billion by 2026, with advancements in Double Arc Forming leading the way.

The unique attributes of Double Arc Forming allow for precision and efficiency. Industries, from automotive to aerospace, are investing heavily in these techniques. Studies indicate that companies utilizing Double Arc Forming can reduce material waste by up to 25%. Despite its advantages, there are areas needing improvement. Many manufacturers struggle to implement these methods fully.

Quality inconsistencies still arise, highlighting the need for better training and equipment. As the market grows, focusing on refining Double Arc Forming processes becomes essential. Companies must adapt or risk falling behind in a competitive landscape. Embracing innovation in this area may lead to significant advancements. The potential is vast, but challenges remain.

Double arc forming techniques have revolutionized how we approach metal shaping. This method allows for creating complex geometries. It combines precision with versatility. Understanding the fundamentals is key to mastering this technique.

Performing double arc forming requires practice. One needs to have a clear grasp of arc functions. Adjusting the heat settings plays a big role. Overheating can lead to weaknesses in the material. This is a common mistake that many encounter. They may rush the process and overlook temperature control.

Tips: Take your time when adjusting parameters. Keep a close eye on the material's response. Document your observations to avoid repeated errors. Even seasoned pros can overlook small details. Insufficient checks can produce varied results. Reflect on each attempt to improve future outcomes.

Double arc forming is revolutionizing various industries, improving efficiency and design flexibility. Key materials play a crucial role in these processes. Metals like aluminum and titanium are often used due to their strength-to-weight ratios. Recent reports indicate that the demand for these materials will grow by 15% annually, driven by aerospace and automotive sectors.

In addition to metals, advanced polymers are increasingly popular. These materials offer lightweight solutions without compromising on durability. They also allow for intricate designs that were previously hard to achieve. The rise of composites is noteworthy. According to industry studies, the composite market is projected to reach $30 billion by 2026. This trend indicates a significant shift in how manufacturers approach double arc forming.

Tips: Choose materials based on project needs. Consider the environmental impact of your material choices. Explore newer options like biocomposites or sustainable sources. Remember, not all materials are perfect for every application. Reflect on past projects to identify areas for improvement.

Double arc forming is a crucial technique in modern manufacturing. It allows for the creation of complex shapes. This method is essential in various industries, from automotive to aerospace. According to recent industry reports, the precision of double arc forming can offer up to 15% cost savings in production. However, improper execution can lead to significant waste.

To implement double arc forming, start by selecting the right materials. Metals like aluminum and titanium are commonly used. This choice impacts the final product's durability and performance. Monitoring temperature and pressure during forming is also vital. Techniques vary, but they should all focus on maintaining consistent arc shapes.

Don’t overlook the importance of operator training. A skilled operator can spot issues early, reducing error. However, even experienced workers may face challenges, especially in maintaining consistent quality. Data shows that 20% of defects arise from operator error. Continuous education and feedback loops can help mitigate these risks. Refining the process often reveals areas for improvement.

Double arc forming is a challenging yet fascinating process. Many manufacturers face common obstacles during this technique. A report from the Forming & Fabricating Industry highlights that around 40% of fabricators encounter issues with precision. Adjustments in machinery setup can often lead to significant errors. This impacts overall productivity and increases waste.

Another frequent challenge involves material behavior. Not all materials respond similarly to double arc forming. According to recent studies, 30% of attempts fail due to inadequate material selection. Proper stress analysis is crucial in avoiding fractures. Many engineers still overlook this step, leading to costly rework. Mistakes in this area reveal the importance of thorough training.

Operators also report difficulties in achieving uniform arcs. This can stem from inconsistent input parameters. Issues arise even with minor variations in temperature or speed. Surprisingly, about 25% of arcs show visible discrepancies in trials, affecting final output quality. Regular maintenance of tools and machines could mitigate these issues. Ignoring this aspect often results in further complications.

This chart illustrates common challenges faced in double arc forming techniques and their corresponding solutions.

Double arc forming techniques are evolving rapidly. Industry experts predict that by 2026, these methods will undergo significant advancements. Reports indicate that the global market for arc forming technology is expected to grow at a rate of 12% annually. This growth highlights the increasing demand for more efficient and innovative forming solutions.

One key trend is the integration of automation. Automated systems can enhance precision and reduce production time. However, these systems also introduce challenges. Training personnel to operate complex machinery will be crucial. A recent survey found that only 40% of companies are investing in worker training. There's a gap that needs to be addressed. The rush to automate may leave some workers behind, creating a skills disparity.

Sustainability is another focus. There's a push for environmentally friendly methods. Reports reveal that businesses are looking to reduce waste, with around 50% aiming for zero waste in production. However, not all companies are executing these initiatives effectively. Many still rely on outdated technologies. The path to sustainable double arc forming is not straightforward, and reflection on practices is essential for industry growth.

| Technique | Material Compatibility | Efficiency (%) | Cost ($) | Innovation Score (1-10) |

|---|---|---|---|---|

| Laser Double Arc Forming | Metals, Polymers | 85 | 15000 | 9 |

| Plasma Arc Welding | Metals | 90 | 20000 | 8 |

| Hybrid Arc Forming | Metals, Composites | 75 | 18000 | 7 |

| Electron Beam Forming | Metals | 80 | 25000 | 6 |

| Arc Flash Forming | Metals | 70 | 12000 | 5 |