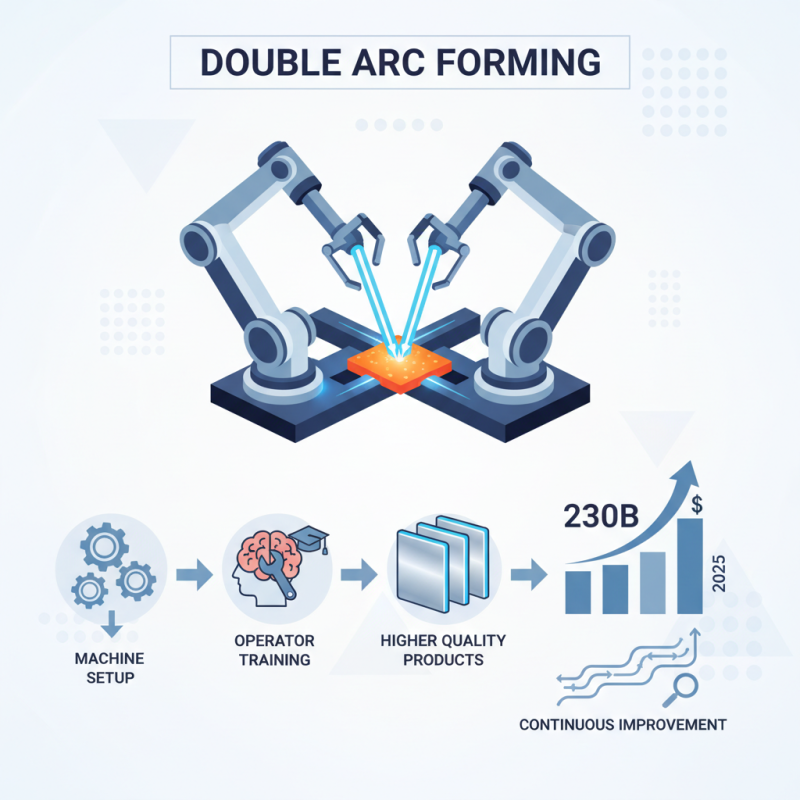

Double Arc Forming is an innovative technique in metalworking. This method provides efficiency and precision in manufacturing. Recent industry reports indicate that the global sheet metal forming market is expected to reach $230 billion by 2025. Double Arc Forming plays a crucial role in achieving this growth.

This technology utilizes two arcs to enhance the forming process. This leads to fewer defects and higher quality products. However, there are challenges. Machine setup can be complex, leading to potential downtime. Ensuring consistent training for operators is critical.

Many companies have adopted Double Arc Forming, but not all see immediate benefits. Some struggle with initial costs and maintenance. Industry reports show that companies that invest in training report better outcomes. A thoughtful approach is essential for maximizing Double Arc Forming's potential. Understanding its intricacies offers room for continuous improvement.

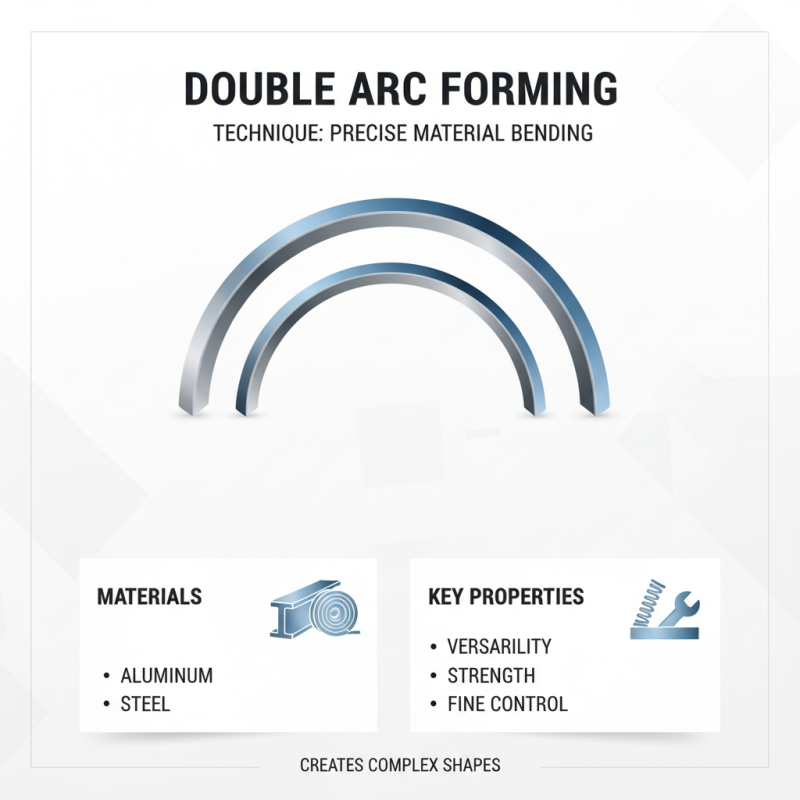

Double Arc Forming is an innovative manufacturing process. It creates complex shapes using two arcs. This technique is particularly useful in diverse industries such as automotive and aerospace. The process begins with a controlled bending of materials. This bending occurs in two different directions, forming the double arc.

The efficiency of Double Arc Forming lies in its precision. By using mathematical algorithms, engineers can predict the outcome of the material deformation. This method often reduces waste and enhances product strength. The result is a well-formed component that meets strict specifications.

Tips: Always ensure proper material selection. Different materials react uniquely during bending. Testing samples before full production can save time and resources. Moreover, it is crucial to pay attention to the bending radius. A slight miscalculation may lead to disappointing results. Continuous evaluation of the process is key to maintaining quality. Inspecting components regularly ensures adherence to standards and solves potential issues early.

| Parameter | Description | Importance |

|---|---|---|

| Definition | Double arc forming is a method used in metalworking that involves bending materials into two arcs. | Essential for creating complex shapes with precision. |

| Materials Used | Typically involves metals such as aluminum, steel, and copper, which can be easily molded. | Choice of material affects flexibility and end-use applications. |

| Applications | Used in automotive parts, furniture design, and architectural elements. | Crucial for innovative design and functionality. |

| Process Steps | Involves heating, bending, and cooling of materials into desired shapes. | Ensures durability and precision in the final product. |

| Benefits | Allows for greater design flexibility and reduced waste. | Enhances sustainability and cost-effectiveness. |

Double Arc Forming is an innovative technique in shaping materials. Its principles are rooted in the manipulation of arcs. Essentially, it involves creating two arcs that intersect or overlap at certain points. This unique method allows for more intricate designs that exhibit both strength and flexibility.

At the heart of Double Arc Forming lies careful calculation. Engineers must consider the material's properties and desired outcome. Each arc's curvature is critical. A subtle change can alter the entire structure's integrity. They often rely on computer simulations to visualize their concepts. However, these digital models cannot always predict real-world behavior.

Challenges abound in the implementation of this technique. Material limitations can hinder the application of Double Arc Forming. Sometimes, the finished product does not meet expectations. Designers must reflect on their choices and adjust their approaches. This process of trial and error is crucial for refining the technique.

Double arc forming is a technique that creates complex shapes through the precise bending of materials. The materials used in this method play a crucial role in achieving the desired results. Commonly, metals like aluminum and steel are favored due to their versatility and strength. Their properties allow for fine control during the forming process.

Beyond metals, various composites are increasingly being utilized. These materials can provide a unique combination of strength and lightweight characteristics. For instance, carbon fiber composites are popular in the aerospace sector. However, they can be tricky to work with. The right mixture and layering must be meticulously controlled to avoid weaknesses.

In addition to metal and composite materials, some flexible plastics are also considered. They can be shaped easily, which is advantageous. Yet, their durability under stress is often a concern. Each material poses its own challenges and advantages. Finding the right material requires careful thought and experimentation. It may involve a learning curve that is not always smooth.

Double Arc Forming is gaining traction in various industries. This innovative process creates complex shapes using two arcs. Its versatility allows for unique applications, especially in manufacturing and design.

One prominent application is in the automotive industry. Double Arc Forming aids in producing lighter, more aerodynamic components. These parts can enhance fuel efficiency. Increasingly, this technique is used to create intricate body panels that improve overall vehicle performance.

In aerospace, weight reduction is key. Engineers employ Double Arc Forming to craft components with precise specifications. These parts often experience high stress, requiring meticulous attention to detail. Maintaining quality while reducing weight can be challenging, but this method shows promise.

Tip: Always test prototypes before full-scale production. It helps in identifying flaws early. Another tip is to iteratively refine designs based on feedback. Embracing imperfections can lead to innovative solutions.

Double Arc Forming is an innovative manufacturing process. It combines two arcs to shape materials effectively. This technique offers several advantages and faces unique challenges.

One significant advantage is material efficiency. Double Arc Forming reduces waste during production. Manufacturers can use more of the material, which lowers costs. Additionally, it allows for complex shapes that traditional methods cannot achieve. This gives designers more freedom. However, achieving the perfect arc balance can be tricky. If the arcs are not aligned correctly, defects may arise.

Tips: Always test materials before full production. Small batches can reveal issues early. Don't hesitate to adjust arc parameters for better results.

A challenge of Double Arc Forming lies in precision. The process requires advanced machinery and skilled operators. Variations in material properties can lead to inconsistencies. This may affect the final product's quality. Monitoring is essential to ensure uniform results. Regular maintenance of tools helps maintain accuracy.

Tips: Invest in quality training for staff. Knowledgeable workers can troubleshoot issues efficiently. Gather feedback from production runs to improve the process continually.